Slowing the spread with Electrostatic Spraying

Why companies should consider adding enhanced cleaning methods, such as Electrostatic spraying, to their FM schedule to reassure and safeguard employees.

In the wake of the pandemic, Covid-19 risk assessments have become commonplace among UK businesses and public institutions. As our news headlines continue to be dominated by Coronavirus developments, companies are having to refocus their attention on how best to safeguard and reassure their employees. Unprecedented adaptations to the way we work, coupled with unpredictable economic variables, have created a requirement to improve upon traditional spray-and-wipe cleaning methods.

It is because of this demand that contract cleaning companies have begun to introduce additional periodic services, such as Electrostatic cleaning, to their service portfolio. Provided alongside routine measures, these enhanced cleaning methods deliver an efficient and affordable solution, supporting clients in combating the spread of viruses, such as Covid-19, in shared spaces.

The procedures implemented vary depending on the location’s population, layout, complexity and nature of business. As a minimum, most sites will now have incorporated; enhanced cleaning procedures, regular hand washing, provision of disinfectant stations, adequate ventilation and allowances for remote or hybrid working, where possible. While these actions do offer a risk reduction, to those occupying the environment, they are subject to inconsistency. Superficial or infrequent cleaning, incorrect selection of product, inaccurate chemical dilution or failure to comply with the guidelines can all lead to unsatisfactory, unsafe conditions. Ventilation, sanitising stations and frequent hand washing are all important exercises in the fight against Seasonal Flu and Covid but are tricky to monitor or enforce. Additionally, while remote working is arguably the most effective defence, it is not practical for all roles and sites

Low footfall buildings, such as quiet offices, may be capable of proficiently disinfecting their environment without the requirement for outside support, however, high traffic areas are likely to require additional measures to combat contamination. It is in the latter instance where stakeholders should consider introducing supplementary professional cleaning services, should they wish to provide the safest possible conditions to their colleagues.

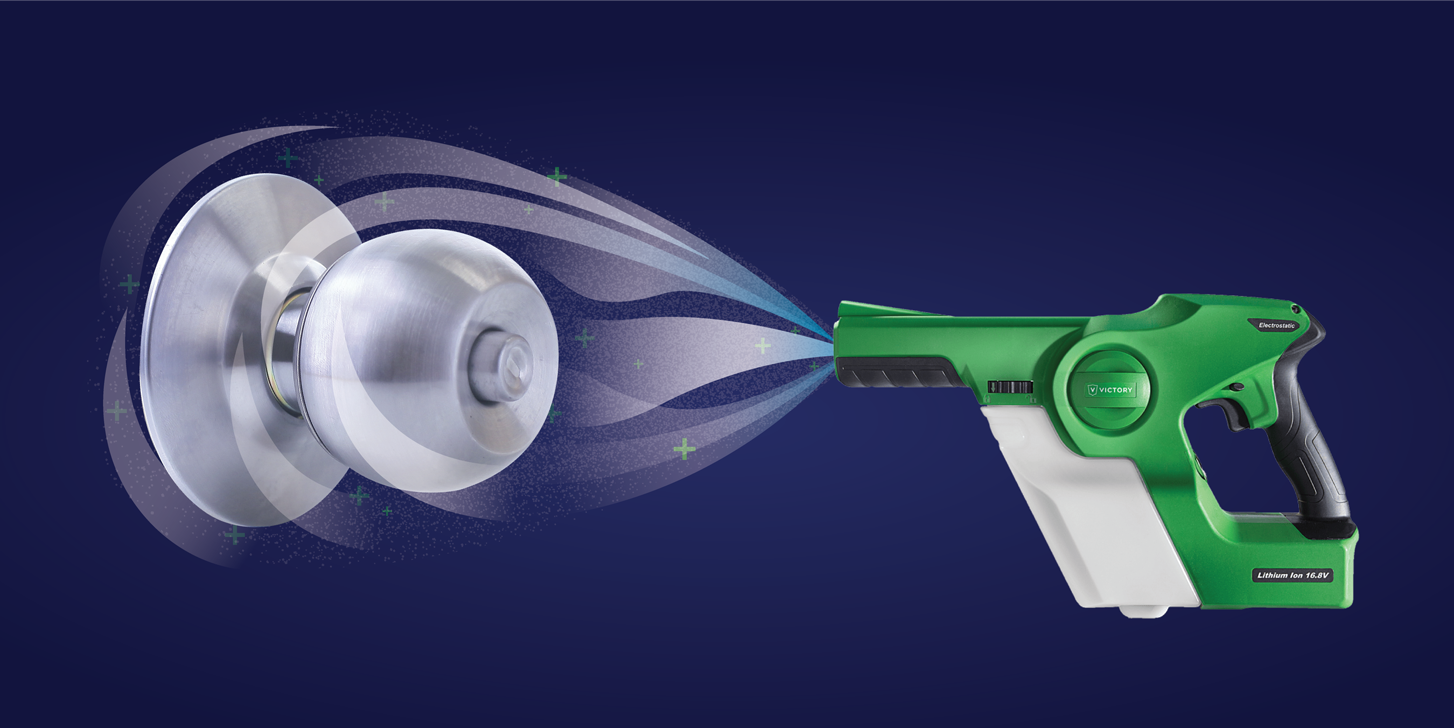

When a client approaches a contract cleaner in this regard, Electrostatic Spraying (ESS) will frequently be featured as a principal remedy – with clear justification. The technology was first patented to Harold Ransburg, an American inventor, in 1941. Originally developed to improve the industrial painting of metal surfaces, it found its refinement within the automotive industry. Its transition to a cleaning application has only come about in the last decade, with a marked acceleration of its development and promotion, to accommodate an ever more hygiene-conscious society.

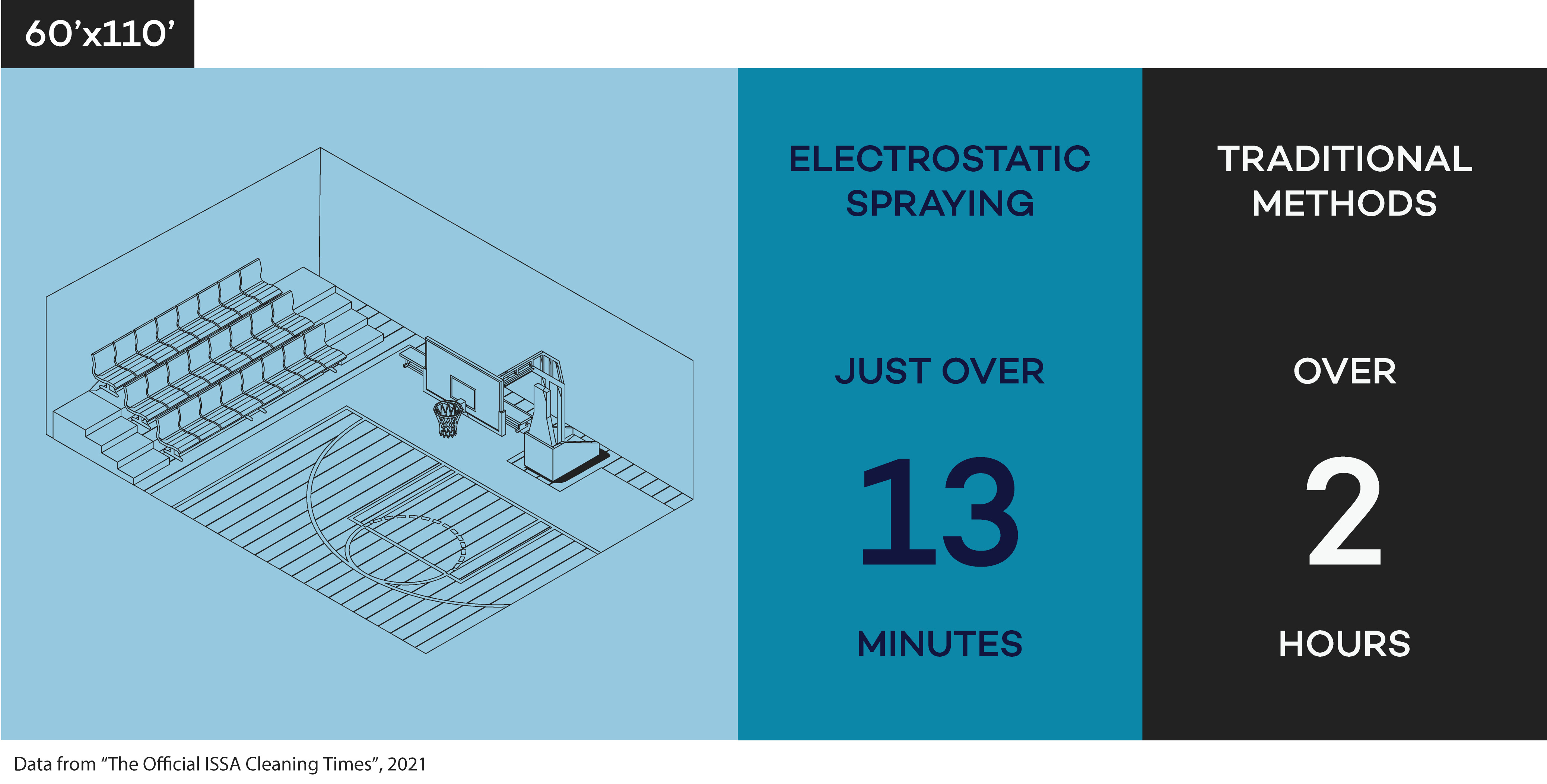

Electrostatic Spraying has proven its capability in removing 99.9% of viruses and bacteria from surfaces, however, this is a statistic often attributed to cleaning and disinfection products. Where this method boasts an advantage is in its effectiveness in providing consistent coverage, even in hard to reach or hidden areas that may otherwise not be captured. A second incentive is the significant labour reduction when compared to traditional methods, such as spray and wipe. Data derived from the Worldwide Cleaning Industry Association’s research suggests that ESS is up to 90% more efficient than traditional methods. When tested in a 60’ x 110’ area, it was found able to accomplish in just over 13 minutes what might typically demand over 2 hours. The widespread adoption into hospital and healthcare settings is a testament to the efficacy of this technique. An industry in which exacting standards of cleanliness are fundamental and resources are often limited can see time-consuming and inaccurate deep cleaning sessions, replaced with a fast and rigorous solution, that requires only a brief wipe-down of visible soiling before commencing.

How does Electrostatic cleaning work?

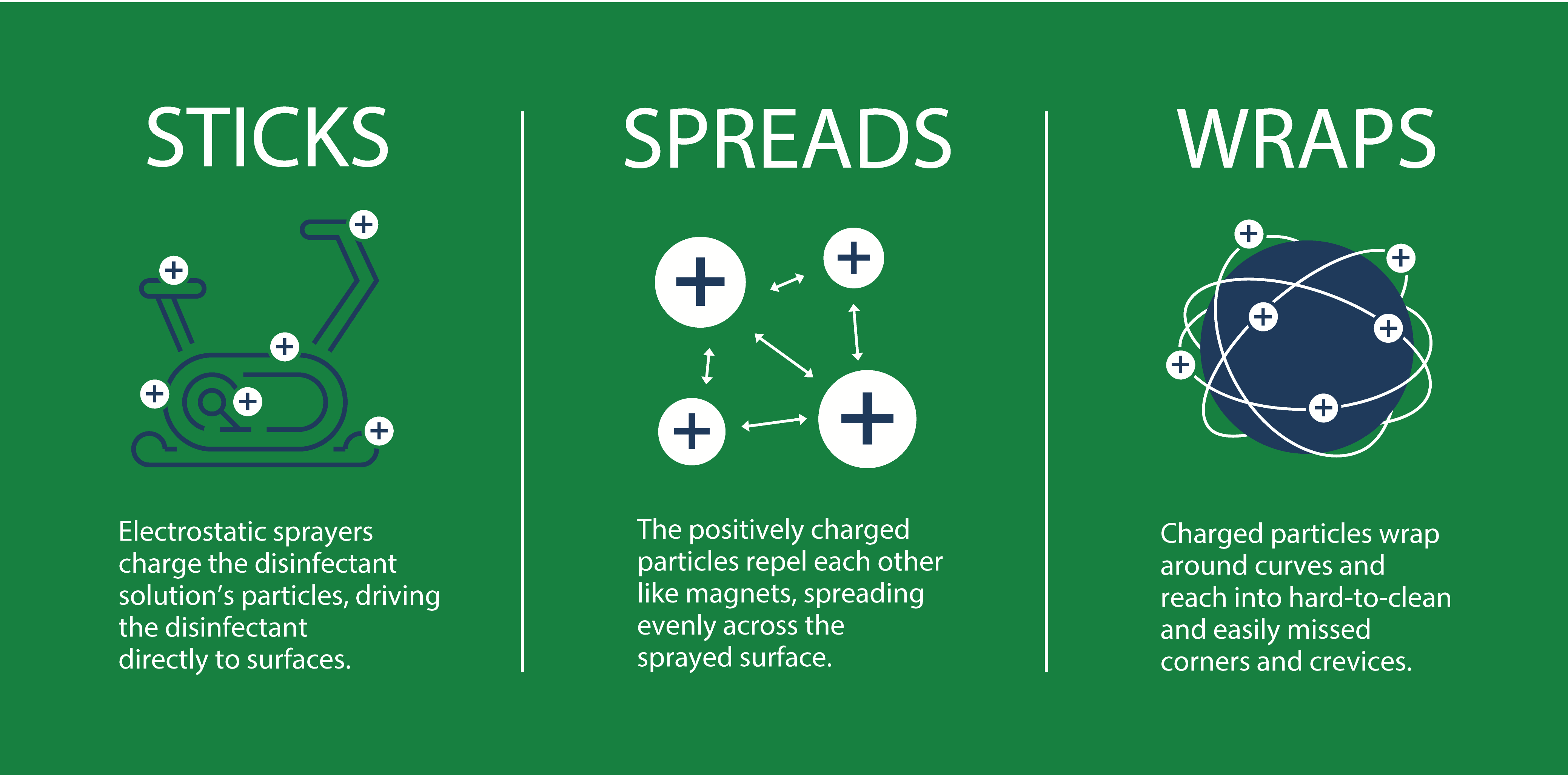

Electrostatic cleaning is a method of disinfection that evenly distributes sanitising fluid, across the desired area. Chemical added to the system’s tank passes through a specialised ring, which applies a positive charge to the substance, before releasing it from the spray nozzle in the form of fine mist. Since most surfaces are negatively charged or neutral, the positively charged particles are attracted and adhered to them, providing a wrap-around effect that results in unmatched coverage. Electrostatic cleaning is a scientifically validated process, which lasts up to 30 days after application, making it the ideal method for fighting the spread of viruses and providing peace of mind in shared spaces.

The Pros and Cons of Electrostatic cleaning

PROS

- Consistent coverage, ensuring that hidden and hard to reach places are equally treated.

- Fire alarm safe.

- Complete surface penetration.

- Lasts up to 30 days from application.

- Effective even in heavily furnished rooms, unlike alternatives such as fogging.

- Mist produced by the sprayer has a fine consistency, making it more economical in its use of the chemical product.

- No advanced room preparation is required.

- The adhesive nature of the mist, due to the positive charge, allows for fast drying and removes the concerns of chemical pooling on surfaces.

- Unlike fogging, which can prevent re-entry for 4 hours+, spaces treated with Electrostatic spraying can be safely re-entered in as little as 20-45 minutes.

CONS

- The action, currently, cannot be performed independent of an operator.

- Possibility of human error, if untrained professionals were to operate the unit, as each surface must receive the proper application of mist.

- Some hand-held versions are equipped with relatively small tanks, resulting in more regular refilling, which adds to the labour intensity of the activity.

- There are selected surfaces, such as those constructed of ‘insulator’ material, that carry a positive charge. Although uncommon, the sprayer may not perform as expected concerning such surfaces

Final thoughts

While various methods of periodic cleaning are available, such as UV Light treatments and fogging, Electrostatic Spraying is typically considered the most effective, affordable and safest option. This is especially true where frequently used or heavily furnished sites, such as offices, are concerned.

Regardless of whether a business engages the services of a contracted professional, or carries out their cleaning in-house, most locations benefit from arranging period assistance, to accompany their traditional spray-and-wipe techniques. This enhanced routine vastly improves the cleanliness and safety of working environments, providing better protection and greater reassurance for employees and visitors.

MAR FM offer a flexible approach, adapting our service to support our clients through this challenging time. If you’d like to discuss how Electrostatic Cleaning could assist your workplace environment, please contact MAR FM.

For more information on Electrostatic cleaning, our datasheet is available to download.

Photography and graphic credit to Victory Innovations Co